EE7.2 and later allow the user to simulate oil spill based on drifters. Oil is maintained at the surface layer and is moved along with the hydrodynamic impacts similar to Lagrangian particles and broken down by evaporation and biodegradation.

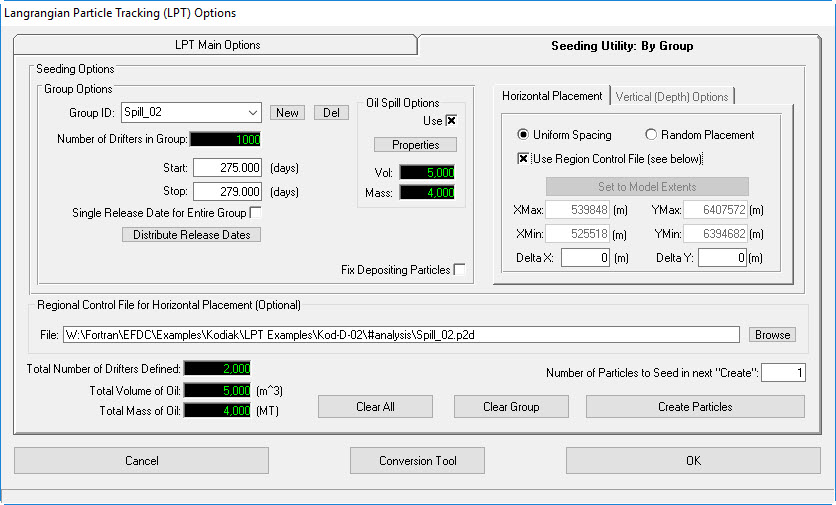

The Seeding Options | Group Options frame is shown in Figure 1 below for oil spill. As there are many types of oils and different weathering of these types of oils, a group should be defined which has its own chemical property and volume per seed. When Oil Spill Options are enabled all the seeding options defined will apply to the group currently selected for the Group ID and the Properties button for oil spill will be enabled. In addition, below the Properties button, the volume and mass of oil for that group are displayed. As oil is always maintained at the water surface the Vertical (Depth) Options and Settling Velocity settings are disabled for oil spill groups.

| Anchor | ||||

|---|---|---|---|---|

|

Figure 1 LPT: Seeding Utility by Group.

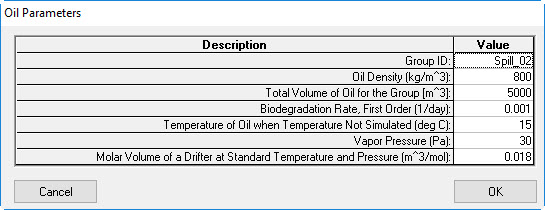

Clicking the Properties button will display the oil parameters settings as shown in Figure 2 . Each oil group requires a separate ID along with the density and the volume of oil per drifter. Biodegradation and vapor pressure are entered to provide the properties for all the drifters in the current group. Though temperature is optional, it is recommended that heat transfer be included, as the oil spill evaporation process depends on the temperature of the ambient environment. Winds also impact evaporation and it is expected that with any realistic oil spill model, winds will be included.

| Anchor | ||||

|---|---|---|---|---|

|

Figure 2 Oil Parameters Setting.

...

For simulation on the oil evaporation process, the theory of surface evaporation presented in the paper of Warren Stiver and Donald Mackay (1984) is used.

EFDC_DSI EFDCPlus allows for effects of biodegradation of the oil based on user defined biodegradation rate with a simple first order decay approach based on Stewart (1993). A rate of 0.011 per day leads to an approximately two month half-life for oil. If temperature of an oil drifter is provided by the user then this is used as the reference rate for the optimal biodegradation.

...